Scientist of the Day - William Arrol

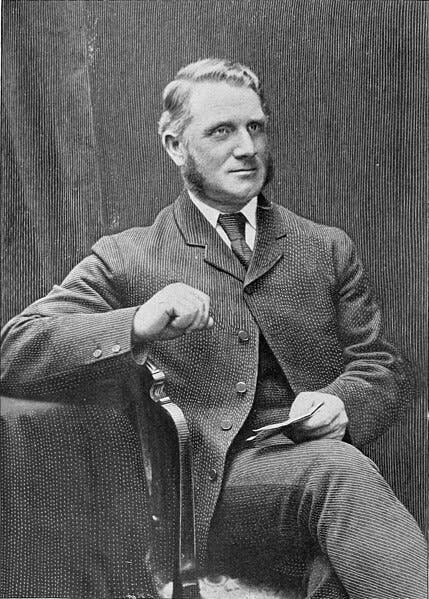

William Arrol, a Scottish civil engineer, died Feb. 20, 1913, at the age of 84. Arrol was not especially legendary, but he was the stuff of which legends could be made, for he created his career himself, entirely from scratch, without much help. He went to work in the mills when he was only 9 years old, and he was apprenticed to a blacksmith four years later. His only schooling was at night, where he learned something of mechanics. He must have done well in his training as a smithy, for in 1863, he joined a company that manufactured bridges, and nine years later, he and a partner founded their own iron factory, the Dalmarock Iron Works in Glasgow. This eventually became William Arrol & Co., one of the leading constructors of iron and steel bridges in the British Isles, and later internationally.

Arrol was responsible for constructing two famous railway bridges, for which he seldom gets credit, for Arrol was a construction engineer, not a design engineer. The two bridges are the second Tay Bridge, and the Forth Bridge, both in Scotland. William Henry Barlow was the design engineer of the second Tay Bridge, and John Fowler and Benjamin Baker designed the bridge over the Firth of Forth. The first Tay Bridge was designed by Thomas Bouch and opened in 1878, and he gets no credit at all, since the central span of his Tay Bridge collapsed in December of 1879, barely 18 months into its short life, with the loss of 75 souls who happened to be aboard a train that was on the bridge at the time. It was a terrible disaster, but little time was spent in mourning, as the bridge was a vital link between the collieries of northeast Scotland and coal-using factories and railways in the rest of Great Britain. The bridge needed to be rebuilt immediately. It was decided to construct the replacement bridge in essentially the same location, but a little to the west, with new piers and abutments, more strongly made this time. Arrol was responsible for providing the iron girders and erecting the spans.

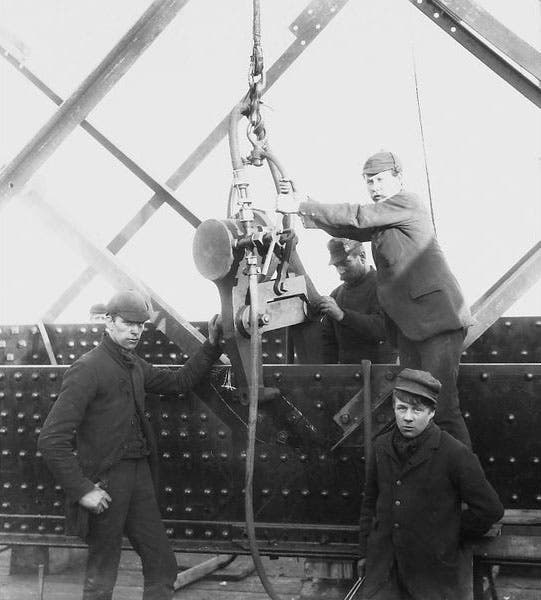

Arrol was a very ingenious engineer. For the Tay Bridge, he had each individual span constructed on a shore-side dock. Since the Firth of Tay is a tidal estuary, when a span was ready to be put into place, he maneuvered pairs of pontoons under the span segment on the dock, and when the tide rose, the span was lifted off its moorings and floated to its new location, where it was lifted into place by hydraulic rams (third image). Beams from the old bridge – the part that hadn't collapsed – were reused, being ferried by pontoons a short distance to their new locations. The old bridge had been single-track and had only two longitudinal beams; the new bridge was double-track and had four supporting lengthwise beams. The old beams were used on the outside, and the principal load-bearing beams in the center were newly manufactured. The new Tay Bridge was finished in 1884 and has been supporting two-way rail traffic ever since. The view we show is from Dundee Law, an extinct volcanic hill in Dundee, looking south (first image).

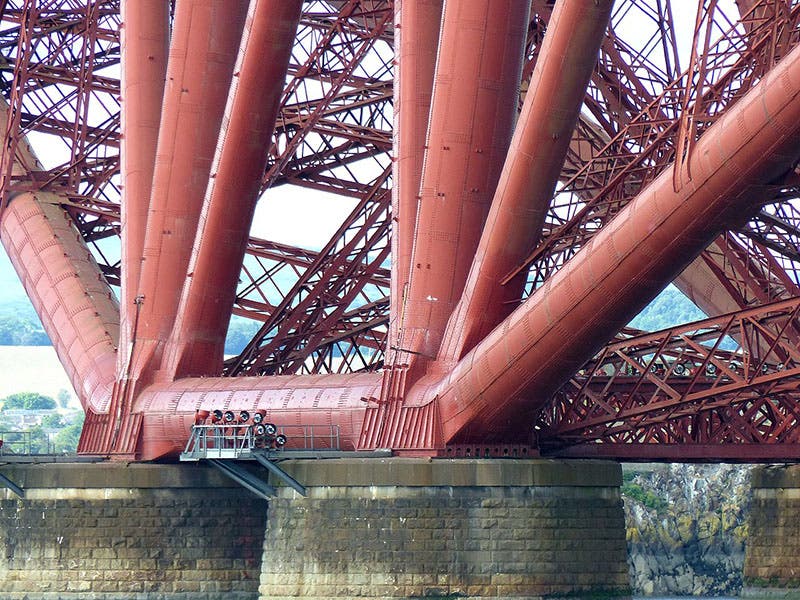

With the initial success of the first Tay Bridge, Thomas Bouch had received the contract to bridge the Firth of Forth, which lies south of the Firth of Tay and connects Edinburgh to the North Sea. Arrol was enlisted to construct and erect the ironwork and girders for the bridge. When the first Tay Bridge collapsed, Bouch's contract was immediately voided, and a new contract was awarded to Baker and Fowler. This bridge, unlike Bouch's design, was to be a cantilever bridge, a massive structure, with three enormous towers, the one in the center a double tower, with the trackway extending out both ways from the towers, balanced by the weight on the opposite side. Arrol was retained to construct the Forth Bridge, but this time he would be working with steel. He began in 1884 by building huge caissons, floating them to the site, and then sinking them – four for each tower. Then he raised the massive towers, slowly extending the cantilevered sections out on either side to keep everything in balance until they could be connected at the centers of the spans. This was the first large bridge ever built of steel, which had finally become affordable with the invention of the Bessemer process. There are several photos of the towers under construction, with the cantilevers creeping out left and right from the towers, at our post on Baker.

One of Arrol’s innovations for the Forth Bridge construction was a hydraulic riveting machine. He late said he had been exasperated by the pay demands of riveters, their irregular work habits, and the sometimes-poor quality of their riveting, so he invented a portable riveting machine that was operated by water under high pressure, could be used in a vertical or horizontal position, greatly speeded up construction, and generated rivets of higher quality than those produced by hammering. We include a photo of Arrol’s hydraulic riveter in use on the Forth Bridge project (sixth image). One of Arrol's riveting machines is on display at the Institution of Civil Engineers (ICE) Museum – Scotland, which just happens to be housed in the Sir William Arrol Building at Heriot Watt University, Edinburgh (seventh image).

The Forth Bridge was a great success, opening in 1890, and it is still in operation. It is, indeed, THE engineering landmark of Scotland, and for many, one of the most impressive engineering marvels in the entire world. Baker and Fowler are credited with the ingenious design, credit that they well deserve. But without Arrol, it would have remained a dream on paper.

Arrol was involved in constructing Tower Bridge in London, and then he turned to politics, sitting in Parliament for some years until his death in 1913. He was buried in Woodside Cemetery in Paisley, Renfrewshire, Scotland, where a memorial stone still stands (eighth image). I wish someone had designed a more appropriate iron or steel monument in his honor.

Four years ago, an ingenious engineer wanted the Lego Group to issue a model of the Forth Bridge. The way this works, you have to construct a model yourself, load images onto a special website for Lego proposals (here is the page for the Forth Bridge), and then seek votes of approval – it takes 10,000 votes for Lego to even consider the idea. Alas, although the proposal did receive the necessary 10,000 votes, it was rejected, perhaps because it was 15 feet long and would require at least three boxes to hold the pieces. But I love the photo of the Lego model posed in front of the real thing (ninth image).

William B. Ashworth, Jr., Consultant for the History of Science, Linda Hall Library and Associate Professor emeritus, Department of History, University of Missouri-Kansas City. Comments or corrections are welcome; please direct to ashworthw@umkc.edu.